Digital twins are transforming the way businesses design, monitor, and optimize systems in real time. What was once a concept limited to aerospace engineering has now evolved into a cornerstone of Industry 4.0. As technology advances, the future of digital twins promises even deeper integration into business operations, reshaping industries with predictive insights, efficiency, and innovation.

What Is a Digital Twin?

A digital twin is a virtual replica of a physical object, system, or process. It uses real-time data collected from sensors, IoT devices, and other sources to mirror the behavior and condition of its physical counterpart. This digital model can simulate scenarios, detect anomalies, and forecast future outcomes — all without interrupting real-world operations.

Core Technologies Powering Digital Twins

- Internet of Things (IoT): Provides live data from physical systems.

- Artificial Intelligence (AI) and Machine Learning: Enables predictive analytics and decision-making.

- Cloud Computing: Facilitates scalability and real-time access.

- 3D Modeling and Simulation: Offers interactive, visual representation of assets.

Applications Across Industries

1. Manufacturing

Digital twins enable predictive maintenance, reduce downtime, and improve product design. Manufacturers use them to simulate production lines, optimize workflows, and ensure product quality before actual assembly.

- Example: A car manufacturer uses a digital twin of an engine to simulate wear and tear under different driving conditions.

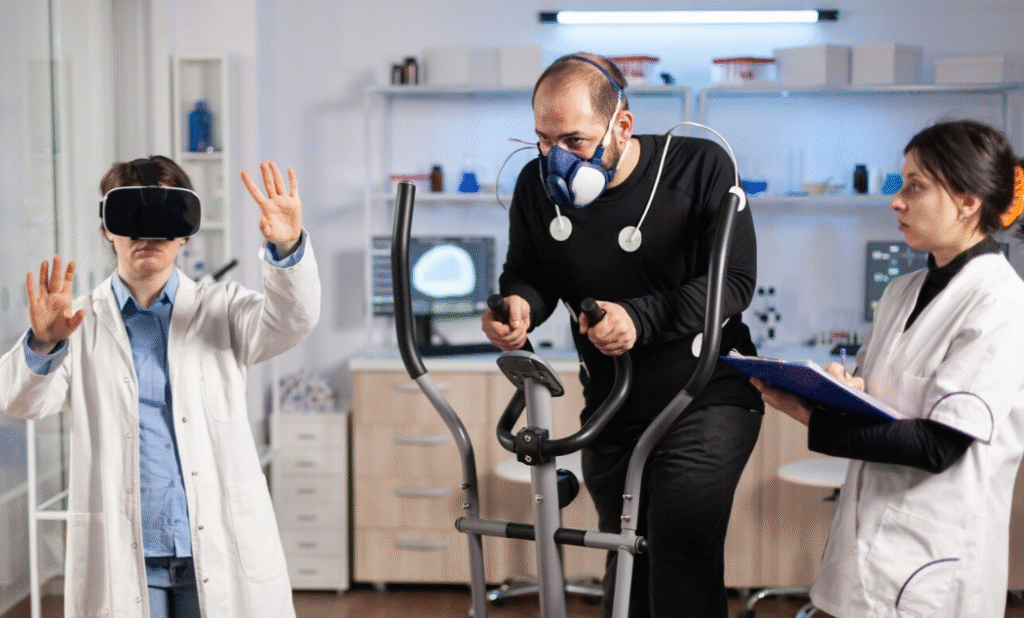

2. Healthcare

In medicine, digital twins of organs or even entire patients can personalize treatment plans. By simulating how a patient might respond to specific therapies, doctors can make more accurate decisions.

- Example: Creating a digital twin of a patient’s heart to test how it reacts to different medications.

3. Construction and Smart Cities

Digital twins are used to model buildings, infrastructure, and urban systems. Planners can assess energy efficiency, safety, and traffic flow before making physical changes.

- Example: A city uses a digital twin to simulate flood response and optimize emergency services.

4. Energy and Utilities

Energy providers use digital twins to monitor grids, predict equipment failures, and plan renewable integration more effectively.

- Example: Wind farms use digital twins to forecast maintenance needs and maximize energy output.

5. Retail and Supply Chain

Digital twins model supply chains end-to-end, allowing businesses to simulate disruptions, optimize logistics, and improve inventory management.

- Example: A retailer creates a digital twin of its warehouse to test different picking and storage strategies.

The Future of Digital Twins

1. Autonomous Decision-Making

As AI becomes more sophisticated, digital twins will shift from passive monitoring tools to autonomous agents capable of making real-time decisions with minimal human input.

2. Integration with the Metaverse

Digital twins could be embedded into virtual worlds, allowing engineers, managers, and stakeholders to collaborate in shared immersive environments.

3. Full Lifecycle Management

In the future, digital twins will cover the entire product lifecycle — from design and production to usage and disposal — offering unprecedented sustainability and efficiency insights.

4. Standardization and Interoperability

To enable seamless adoption across industries, digital twin platforms will likely move toward universal standards for data formats and communication protocols.

Challenges to Overcome

- Data Privacy and Security: Sensitive data from physical assets must be protected.

- High Implementation Costs: Developing accurate digital twins requires investment in infrastructure and expertise.

- Complexity in Integration: Integrating digital twins with legacy systems can be difficult.

Conclusion

Digital twins represent a major leap forward in how businesses understand and interact with their assets and environments. By creating a dynamic, data-driven bridge between the physical and digital worlds, they empower organizations to optimize performance, reduce risk, and innovate faster. As the technology matures, digital twins will become integral to operations across virtually every sector — not as a novelty, but as a necessity.